The World’s Finest Grooved Metering Rods – Certified for Quality

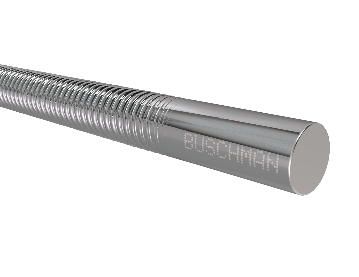

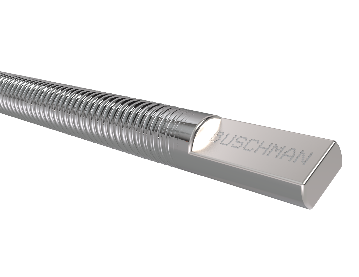

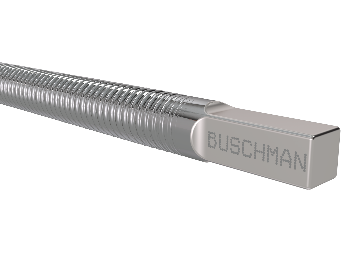

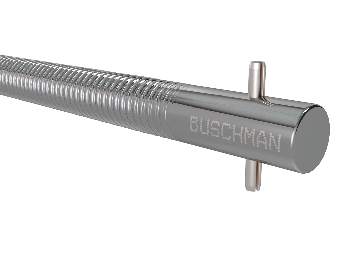

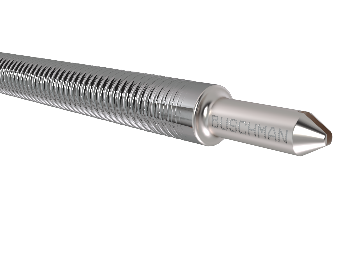

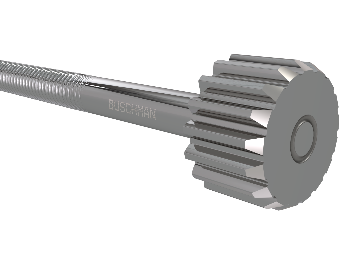

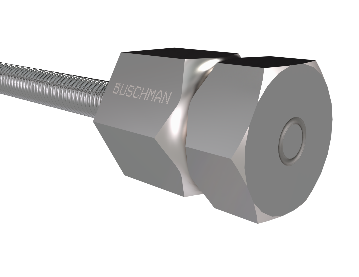

Grooved metering rods (also known as rollformed rods and threaded rods) are stainless steel rods with precision threads cold-formed into their surface. By adjusting the size of the thread, coat weights can be precisely controlled. By adjusting the shape of the thread, the rod can be optimized to provide the most smooth and uniform coating possible for your application.

Paper mills and converting mills use grooved metering rods to coat starches, pigments, adhesives, and other coatings onto paper, films, foils, cardboard, and other surfaces.

Buschman grooved metering rods are the highest quality in the world.

Buschman’s coating optimization process ensures that every rod we produce meets the world’s most stringent standards for precision, quality, and consistency. Every thread is precision-engineered to optimize the coating process, thus allowing for more precise and cost-effective metering than is achievable with wire-wound rods.