More than 100 years after wire-wound coating rods, or “Mayer” rods, were invented, they are still in use in some paper coating operations.

But as coating applications have evolved and performance requirements become more demanding, today’s users are finding that wire-wound Mayer rods increasingly fall short of their needs.

Modern paper coatings are more abrasive, contain higher percentages of solids, and coat a much larger variety of substrates. To effectively apply these types of coatings in more complex applications – and meet increasingly stringent quality standards demanded by their customers – more and more paper mills, linerboard manufacturers, and converters are transitioning to rollformed, or grooved rods.

Are wire-wound rods still the right choice for your coating operation or should you switch to rollformed rods? How difficult is the transition?

Here are some factors to consider.

How Rollformed Metering Rods Modernized Paper Coating

Wire-wound rods were the metering rod standard for paper coating for decades. Then, in the 1980s, rollformed metering rods were invented, with engineered threads built into the rods themselves.

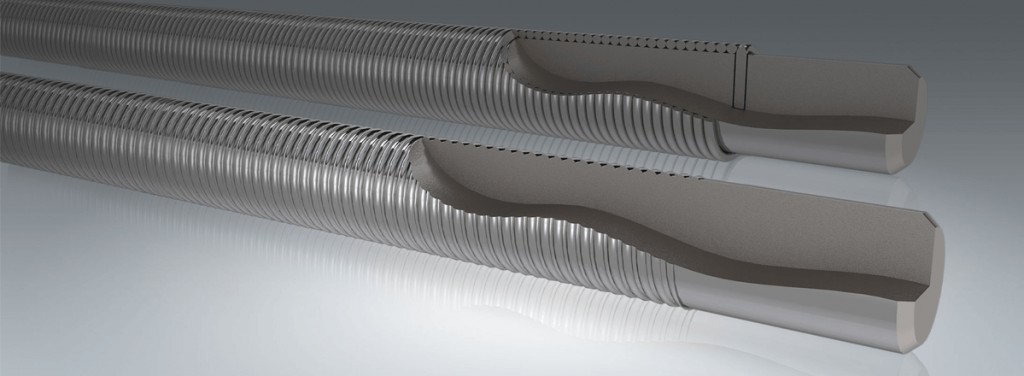

Unlike wire-wound rods, which are limited to a profile consisting of round cross-sections positioned side by side, the shape of the rollformed profile, or thread shape, can be adjusted to fit the requirements of the application, as shown in Figure 1.

By allowing users to more precisely control their coating application and extend rod life, rollformed rods transformed the paper coating process and set a new standard for the industry.

Gaining Control of Critical Rod Performance Variables

Both wire-wound and grooved rods control application volume by the area of the valleys between the wires or thread peaks. But unlike wire, the shape of the thread profile on a rollformed or grooved rod can be custom engineered and manipulated to precisely control critical rod performance variables, tailoring the rod to a specific coating application.

In most cases, optimizing the thread on your metering rod will increase coating quality and efficiency. This translates into:

- Longer runs between rod changes;

- More uniform coatings;

- Higher quality coated products, and;

- More efficient coating runs.

In addition, rollformed or grooved rods are more durable, easier to clean, and have a more uniform surface than their wire-wound counterparts. There are no wires to break and no tight spaces between wires to collect dried coating, large coating particles, and air bubbles.

These benefits are often realized immediately upon the transition from wire-wound to rollformed metering rods.

Common Coating Challenges: How Wire-wound & Rollformed Rods Compare

There are many common issues and quality problems involved in paper coating. Figure 2 shows how wire-wound and rollformed rods compare in relation to solving these problems:

No adjustments can be made to the profile shape.

Shape of the thread can be engineered to optimize the application, providing higher quality finished coating.

Sharp valleys between wire are difficult to clean.

Open root shape of the thread makes cleaning much easier.

Sharp valleys between wires easily trap coating particulate and debris.

Thread shape can be optimized to keep rods cleaner during operation.

Smaller diameter wires are easily broken during handling and use.

Rollformed rods have no wires to break and are much more durable.

Wire is softer than rollformed threads. Therefore, wire wears much faster.

Harder surface finish and engineered thread crests creates a longer-lasting rod.

Overall diameter of rod increases by twice the wire diameter. This can cause drive alignment and other issues.

The outside diameter of a rollformed rod is much less variable than wire-wound. This eliminates alignment issues when changing sizes.

FIGURE 2

Rollformed Rods Offer Valuable Quality & Efficiency Advantages

If you are still using wire-wound rods in your rod-coating application, you are missing out on the significant quality and efficiency advantages of rollformed or grooved coating rods.

Figure 3 shows a wire-wound profile compared to two very different threaded profiles.

Profile A has an elongated crest to maximize surface contact with the substrate being coated. Extending the crest in this way creates a rod that will last much longer, as there is more surface area in contact with the substrate.

Profile B has an extended root area. This extended root can be ideal for high solids and high-viscosity coatings that might not otherwise flow well through a wire-wound rod or a rollformed rod with a more closed root.

The correct thread profile can allow you to increase the percentage of solids in your coating, thus reducing dryer time and energy costs. If you have a very low viscosity coating, a thread might be designed to extend the life of the metering rod itself.

How to Transition from Mayer Rods to Grooved Metering Rods

For more and more paper coaters, the benefits of rollformed or grooved rods are clear.

Fortunately, the transition from wire to grooved rods is a painless process. In most cases, a suitable grooved rod can simply replace the wire-wound rod with no equipment modifications required.

The first step is determining the correct thread size for your application. Buschman grooved rod threads are sized in the same way as their wire-wound cousins. So, a #10 Buschman grooved rod would apply the same amount of coating as a rod wrapped with 0.010in wire. In practice, a grooved rod may apply slightly more coating volume than a wire rod due to the more efficient fluid flow (higher yield) through the thread as compared to through the narrow root between the wires.

After thread size, which determines coat weight, thread contour shape (aka: profile) is the next most important factor to consider when choosing a metering rod. The shape of the threads will have a major impact on the quality of your coating and can have significant impacts on efficiency and costs in other parts of your operation.

Partner with Your Metering Rod Manufacturer for Success

When transitioning to grooved rods from wire, it’s vital to work closely with your metering rod supplier. Based on your feedback, they will be able to optimize the thread for your application.

Buschman is one of the world’s leading manufacturers of metering rods. Because of the numerous advantages grooved rods offer, 90% of the rods Buschman produces today are rollformed.

Many factors go into determining the correct thread profile and Buschman has many decades of experience in optimizing thread profiles to meet the most challenging coating applications. If one of our more than 26 thread shapes isn’t right for your application, we will engineer a new profile specifically for your application. Contact us to learn more.