In the world of liquid coating application, the size of your metering rod matters – but perhaps not in the way you’d initially think. While a larger diameter rod may offer a longer lifespan due to the greater circumference providing more wear surface, this advantage is often overshadowed by the exponential growth of the rod’s cross-sectional area – and consequently, its cost.

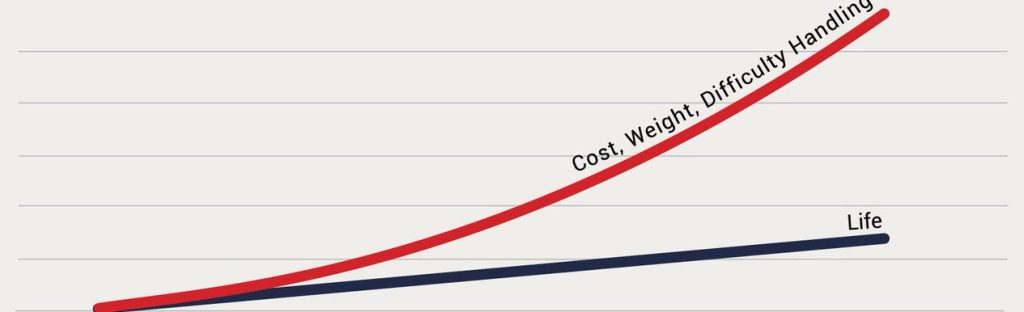

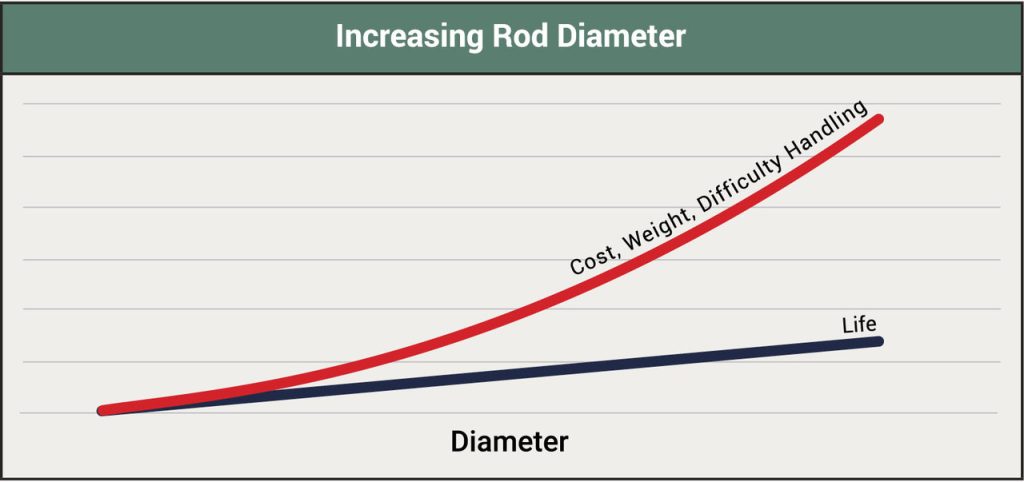

The graph shown in Figure 1 shows a visual representation of this principle. While the surface area (and therefore the service life) of a rod grows linearly with diameter, the internal volume of the rod increases at a much faster rate on an exponential curve. This illustrates why a larger diameter rod doesn’t always equate to a better value proposition.

FIGURE 1

This leads us to one of the key advantages of smaller diameter rods: their high surface area to cross-sectional area ratio. Smaller rods have more surface area relative to their volume, translating into a more cost-effective wear surface. This means you get more ‘bang for your buck’ in terms of the lifespan of the rod compared to its cost.

But the benefits of smaller rods extend beyond cost-effectiveness. They can also play a role in enhancing coating quality. In particular, their smaller diameter can help improve the process of film split. A small diameter rod can facilitate a cleaner film split, as evidenced by a more uniform coating application, with reduced defects such as a blotchy or orange-peel appearance that can occur with larger rods.

Furthermore, their inherent flexibility allows them to better accommodate variations in the substrate surface and makes it easier to profile to a backing roll. This adaptability enhances the coating’s quality, ensuring a smooth and consistent application even on substrates with slight irregularities.

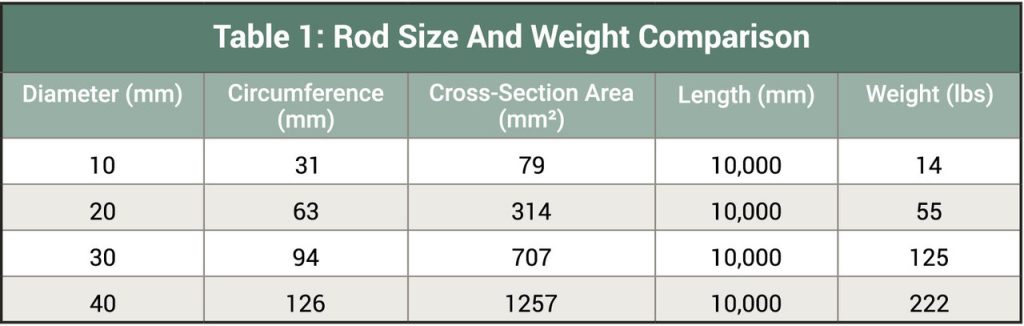

Another factor to consider is weight. As shown in Figure 2, a rod with a diameter of 10mm and length of 10 meters weighs about 14 pounds, while a 30mm rod of the same length weighs a hefty 125 pounds. That is a 9x increase in weight for only a 3x increase in maximum service life. This dramatic increase in weight has implications for worker safety and ease of operation. The lighter weight of smaller rods reduces the risk of injury when installing or replacing rods, and it can make for smoother operation.

FIGURE 2

In summary, smaller diameter metering rods present a compelling value proposition. They provide a more cost-effective wear surface and ensure high-quality coating application. So, before defaulting to larger rods under the assumption that bigger equals better, consider your options. Smaller metering rods could deliver superior results, not just for your product quality, but also for your operational efficiency and bottom line. When considering the balance between efficiency, quality, and cost, smaller sometimes really is better.