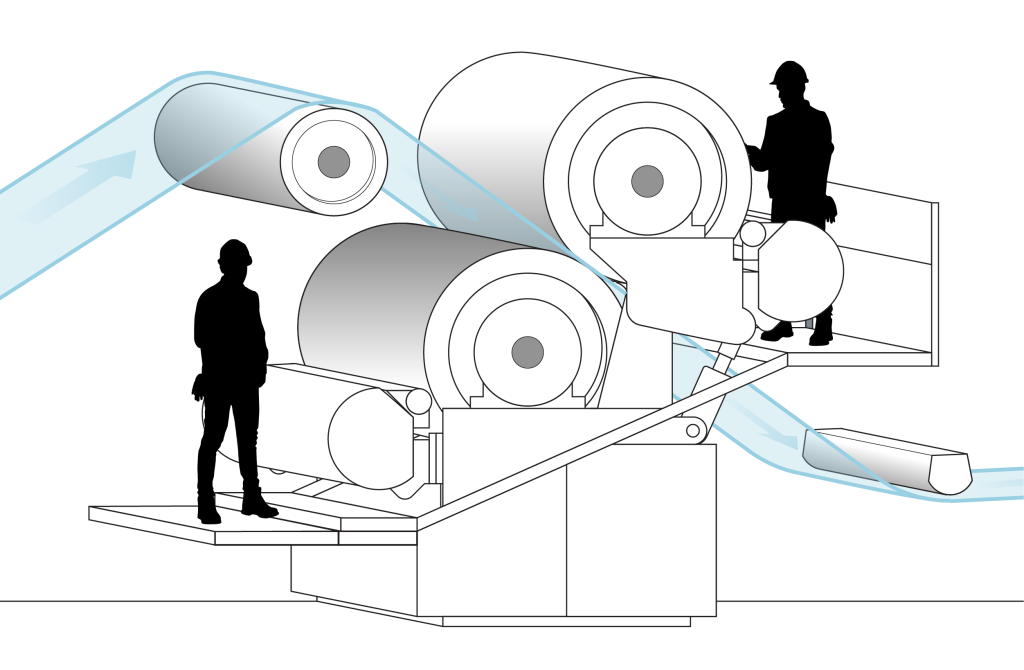

A rod metering size press (RMSP), also known as a size press or film press, is an important component in the papermaking process.

Figure 1 above shows a typical RMSP setup. As the paper (shown in blue) moves through the press, a thin layer of surface sizing agent is applied to the front and back of the paper to improve its surface properties, such as smoothness, strength, printability, and resistance to liquid penetration.

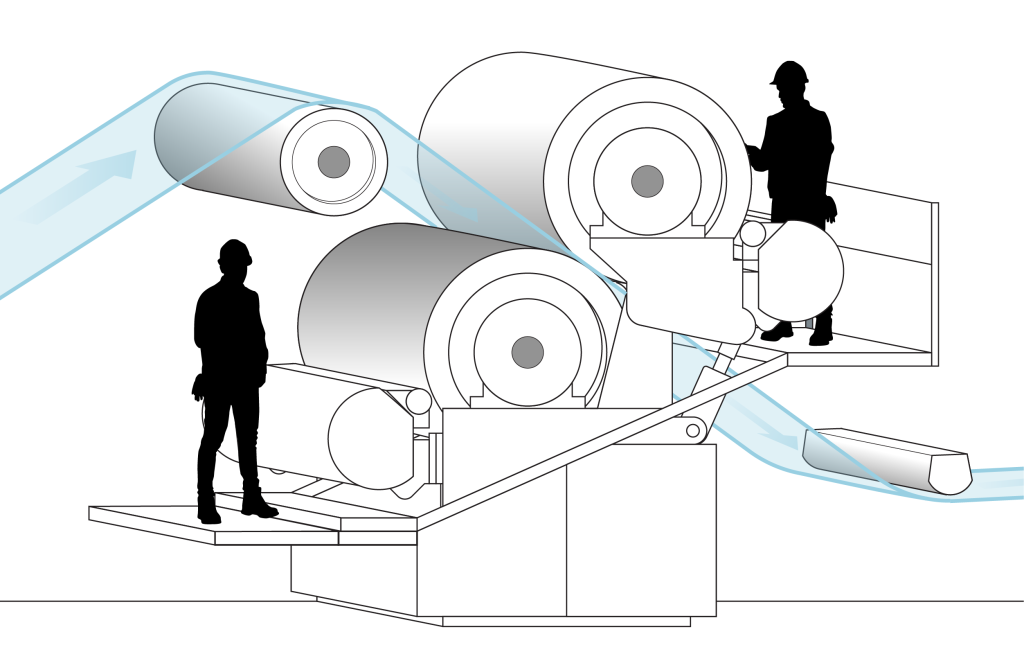

Figure 2 shows the location of the coating chamber in the RMSP. A precision metering rod within the coating mechanism is used to apply and control the exact volume of a sizing agent (starch, shown here in red) to the surface of the paper.

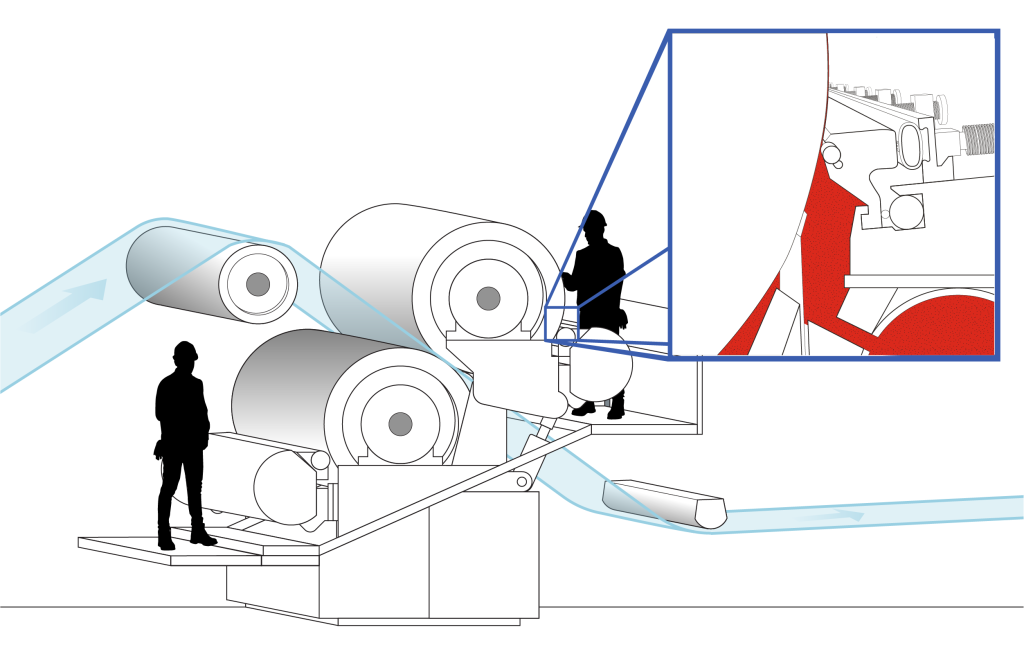

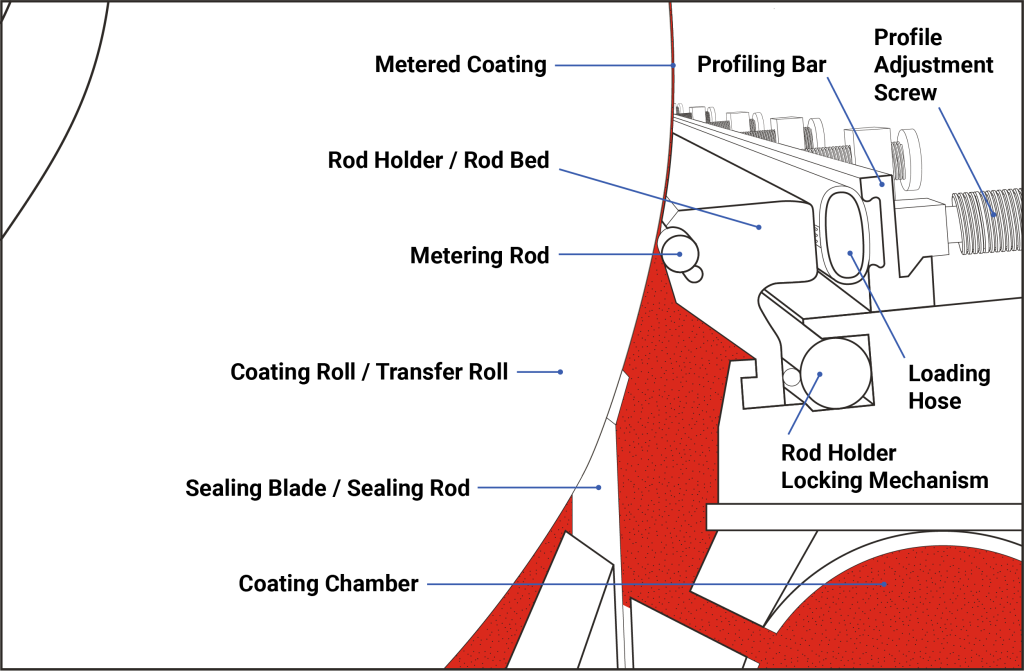

Figure 3 shows a detailed view of the coating chamber where the metering rod that controls coating meets the pickup transfer roll. The rod is secured within a rod holder/rod bed by snap fitting the rod in place. Coating (shown in red) flows from the coating chamber to the rod, which volumetrically controls the application of the coating to the transfer roll.

How to Optimize Paper Coating with an RMSP-7 Tips for Success

Here are seven important aspects to optimize paper coating with a rod metering size press:

- Rod Thread Design: The thread design of the rods is crucial for achieving uniform and controlled application of the sizing agent.

Rods should have a precise diameter, a smooth surface, and proper alignment to ensure consistent coating thickness across the web. But the contour shape of the thread profile is one of the most critical elements of achieving coating uniformity across the face width of the press – and the viscosity, temperature, and percent of solids of the coating often determines the best shape.

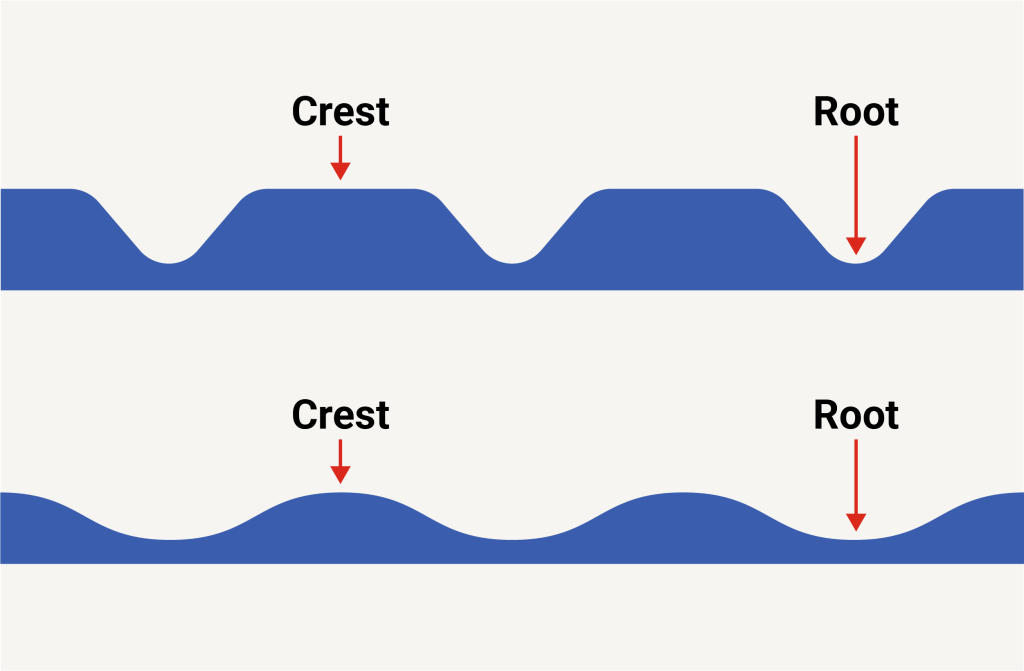

Figure 4 shows two examples of contour shapes in a metering rod thread profile. For lighter viscosities, a wider crest, as shown in the first shape below, may be best for extended rod life. Heavier viscous coatings are best applied with a contour shape that has a more open root with a narrow crest profile, like the second shape shown below.

- Coating Thickness Control: The ability to control and adjust coating thickness is essential to achieving desired surface properties. The size press should have mechanisms or controls to dial in and regulate how the rod is used to deliver the amount of sizing agent being applied to the paper web.

However, the primary component for controlling coating thickness on a rod metering size press is the thread size of the grooved rod. Too often paper makers try to control multiple coat weights by using one size rod and then increasing rod load pressures to achieve lesser coat weight. This places unnecessary wear and tear on the backing roll, bearings, power, rod, and rod holder, and eventually ends up costing a lot more.

There is simply no substitute for using the correct rod thread size to achieve the target coat weight and changing rod size to achieve other coating thicknesses as needed. - Rod Diameter: In a rod metering size press, larger diameter metering rods can be more difficult to profile and maintain compared to smaller diameter rods.

Larger diameter rods have increased sensitivity because a larger surface area is in contact with the transfer roll. This makes the rods more sensitive to variations in coating properties, such as viscosity and flow rate. Even slight changes in these parameters can have a more significant impact on the coating thickness when using larger diameter rods.

A larger diameter rod can sometimes allow more material to flow due to a hydroplane effect between the rods and the transfer roll. This can create a larger wedge that results in the application of a thicker coating. However, the rigidity of larger diameter rods can be more difficult to work with than smaller diameter rods. This increased stiffness can make it more challenging to achieve precise, uniform coating thickness across the entire width of the transfer roll

Also, rod load pressures required to hold the rods while keeping them in the profile position can make variations in coating thickness and consistency a challenge in the application. Careful design considerations, precise machining, and meticulous control of process parameters are required to overcome these challenges when working with larger diameter metering rods.

Advanced technologies such as automated control systems, real-time monitoring, and feedback mechanisms can be employed to optimize the profiling of larger diameter rods in a rod metering size press. Here’s more on large diameter rods. - Coating Formulation: The selection and formulation of the sizing agent is vital to successful coating with a rod metering size press. The agent should be compatible with the paper grade and desired properties, such as enhancing water resistance and/or ink holdout. Factors like viscosity, solid content, and rheological properties of the coating formulation should be optimized.

In the paper industry, for example, starch is used as a binding agent and a coating material. It’s always enticing to buy “cheap” or “local” starch and other coating elements, but these starches may not always deliver the desired functional properties or effects.

Here are some of the issues with cheap starches:

- Higher usage levels may be required to achieve the target results. This can increase production costs and energy because more starch is needed for the same effect. Higher-quality starches are often more efficient, requiring lower quantities to achieve the desired performance.

- Properties of cheap starches may be inconsistent from batch to batch, which can lead to variations in performance and make it challenging to achieve consistent results in manufacturing processes.

- Cheap starches may be sourced from less sustainable or environmentally responsible practices. Higher-quality starches typically come from reputable suppliers who adhere to sustainable sourcing practices, ensuring better environmental and social standards.

- Cheap starches also may be contaminated with dirt and debris, which can eat away at the beam that houses the rod holder (bed) that holds the rod. Once the interior of the beam has been eroded away by the contamination, the only remedy is to contact the Original Equipment Manufacturer (OEM) and rebuild the beam, which is costly and time-consuming.

- Rod Holder (bed): Rod holders are essential components in the rod metering size press coating process. They ensure the rod is held in place while allowing the rod to rotate inside the holder cradle with minimal turn resistance, which improves efficiency.

In a rod metering size press, a continuous flow of water into the rod holder irrigates the bed, which lubricates, quasi-washes, and minimizes heat buildup of the rod in the cradle. This prevents the sizing agent from drying and accumulating on the rods, to avoid uneven application or damage to the paper. The water also helps maintain the proper consistency and viscosity of the sizing agent, ensuring a smooth and consistent application onto the paper surface.

By properly irrigating the holder, excess sizing agent is washed away, preventing buildup and allowing for better control of the application process. This helps maintain the efficiency and effectiveness of the rod metering size press in producing high-quality paper products.

For proper water pressure, see Original Equipment Manufacturer (OEM) specifications, but if none are found, we suggest no more than 5 PSI water pressure in the irrigation channel.

Rod holder material is customarily hot cast Polyurethane (PU) or Ultra High Molecular Weight Polyethylene (UHMW-PE). Here are contrasts between these two options:

PE (Polyethylene) Rod Holders

PU (Polyurethane) Rod Holders

Cost-effectiveness: Polyethylene is generally less expensive compared to polyurethane, making it a more budget-friendly option. Flexibility and elasticity: Polyurethane exhibits excellent flexibility and elasticity, allowing it to absorb impact and return to its original shape. This property can be beneficial in preventing damage to the rod and providing a secure grip.

Chemical resistance: PE has good resistance to a wide range of chemicals, including many solvents and acids commonly used in coatings.

Due to its elasticity, the lips of the holder are softer and grip the threads for minimal leakage. Durability: Polyethylene is known for its durability and can withstand impact and wear well, making it suitable for demanding environments. Chemical resistance: While PU can generally resist many chemicals, it may not be as resistant to some solvents or aggressive chemicals compared to PE. It is advisable to check the specific chemical compatibility of the polyurethane material being used.

UV resistance: PE has moderate resistance to UV radiation, but long-term exposure to sunlight can cause degradation over time. It is advisable to use UV-stabilized PE for outdoor applications.

UV resistance: Polyurethane can have good resistance to UV radiation, especially if it is formulated with UV stabilizers. This makes it more suitable for outdoor applications and helps prevent degradation from sunlight exposure.

- Maintenance and Cleaning: Regular maintenance and cleaning of the size press is crucial to ensuring optimal performance.

Rods should be inspected, cleaned, and replaced if necessary. When new or reground transfer rolls are installed, the rod should be profiled to match the surface of the transfer rolls. Proper lubrication of mechanical components and monitoring of wear and tear are essential to avoid disruptions in the coating process. Since the rod is a small part of the manufacturing cost, it’s best to avoid taking chances with a worn rod. Replace it with a new rod to ensure optimum coating. Monitoring Rods - Quality Control: Implementing a robust, inline quality control system is important to monitoring and assessing coating quality. This can involve periodic sampling and testing of coated paper samples to verify properties such as coating thickness, smoothness, porosity, and printability.

An efficient, well-maintained rod metering size press with precise control over coating thickness and uniform application is essential for achieving consistent, high-quality coated paper products.